About MBLI’s Demand Chain Management Service (DCM)

What Is DCM?

Retailers continue to assign increasing importance to achieving strong in-stock performance, low levels of inventory, and decreased risk of inventory obsolescence while simultaneously offering expanded and unique product offerings. Compounding the challenges presented by these retail objectives, product supply chains have grown in complexity and also in their sensitivity to customer and product trends, with many retailers placing stronger emphasis on the importance of their own higher margin proprietary and private label product offerings. Such a merchandising strategy results in higher exposure to out-of-stocks, obsolete inventory, and increased logistics expenses. Nevertheless, new, different, and unique remain the primary merchandising goals of most convenience retailers today.

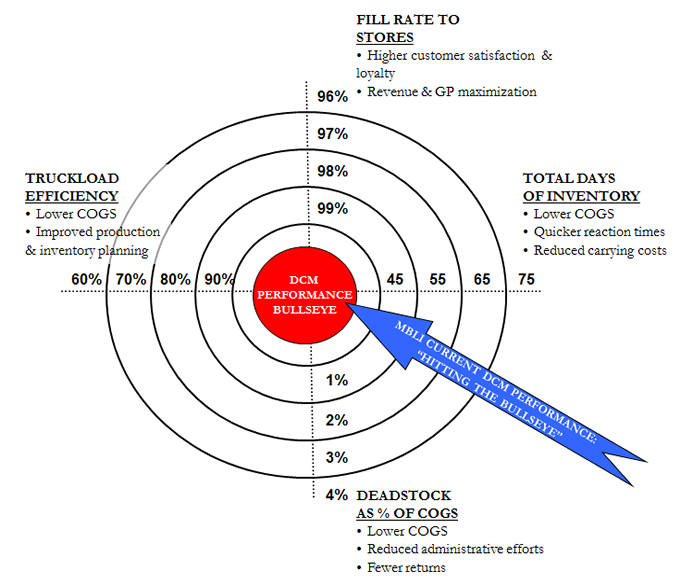

Through its partnerships with convenience store operators and foodservice wholesale distributors, Mitsui Bussan Logistics, Inc. (MBLI) has developed and refined the methods, systems, and business processes utilized to help product supply chains gain flexibility and responsiveness, while improving performance in key supply chain metrics, and lowering costs. Ultimately, MBLI seeks to provide convenience retailers and their upstream partners with concurrent improvements in:

- Wholesale and retail in-stock %

- Upstream logistics expenses

- Overall inventory levels

- Inventory obsolescence rates

Refer to the illustration below for a depiction of MBLI’s demand chain service objective.

How Does MBLI Deliver Its DCM Service?

From its operations center in Dallas, Texas MSSI micro-manages and regulates the flow of products originating from both domestic and off-shore sources and through a network of unique distribution channels. MSSI uses customized software and proprietary business methods along with VMI and EDI based connectivity to enable effective DCM. Facilitating logistics savings and efficiency, MSSI operates several strategically located “Transfer Centers,” which are used to provide efficient truckload consolidation of products for which direct-to-distributor shipments are not cost-effective. Transfer Centers also serve as rapid replenishment points to quickly respond to the inevitable volatility of customer demand. These multi-purpose Transfer Centers play an important role in delivering MSSI’s cost saving DCM service.

Specifically, MBLI’s DCM service encompasses the following activities:

- Item level forecast and production collaboration, including lifecycle planning

- Order planning and inventory replenishment (both VMI /EDI and other methods)

- Daily micro-management of inventory positions and movements

- Efficient utilization of Transfer Centers for the recombination of inbound and outbound truckloads

- Robust item registration verification protocols

- Tactical management of supplier relationships

- Detailed tracking and reporting of excess and slow moving inventory

- Upstream transportation and logistics coordination, including reverse movements as requested

- Delivery coordination, monitoring, and proactive trouble-shooting

- Transaction verification and settlement among partners

- Proactively communicating critical product and promotional dependencies and issues